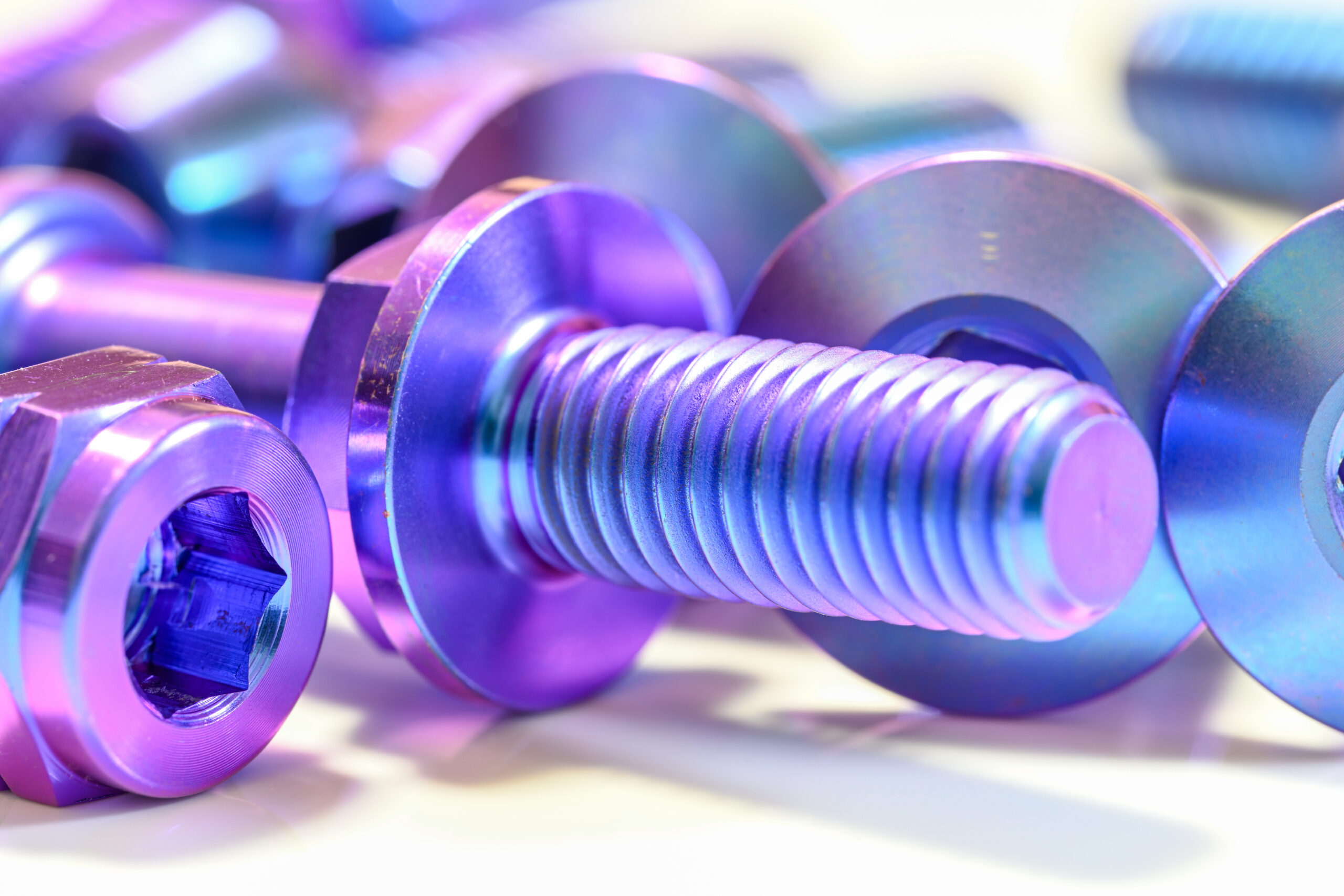

Corrosion is one of the most persistent threats to naval platforms. In marine defence environments, constant saltwater exposure, humidity and temperature fluctuation can compromise even high-performance materials. For this reason, selecting the right marine fasteners is critical to maintaining the safety, reliability and longevity of naval systems. While marine hardware is widely used across commercial maritime industries, defence platforms operate under more demanding conditions. This article explores how corrosion affects fasteners in naval systems, what differentiates defence-grade solutions, and how the right material and specification prevent failure. Need corrosion-resistant fasteners for naval defence systems? JP Aero supplies certified marine fasteners with full traceability and technical support for demanding aerospace and defence environments. Contact our team today for more information. Why