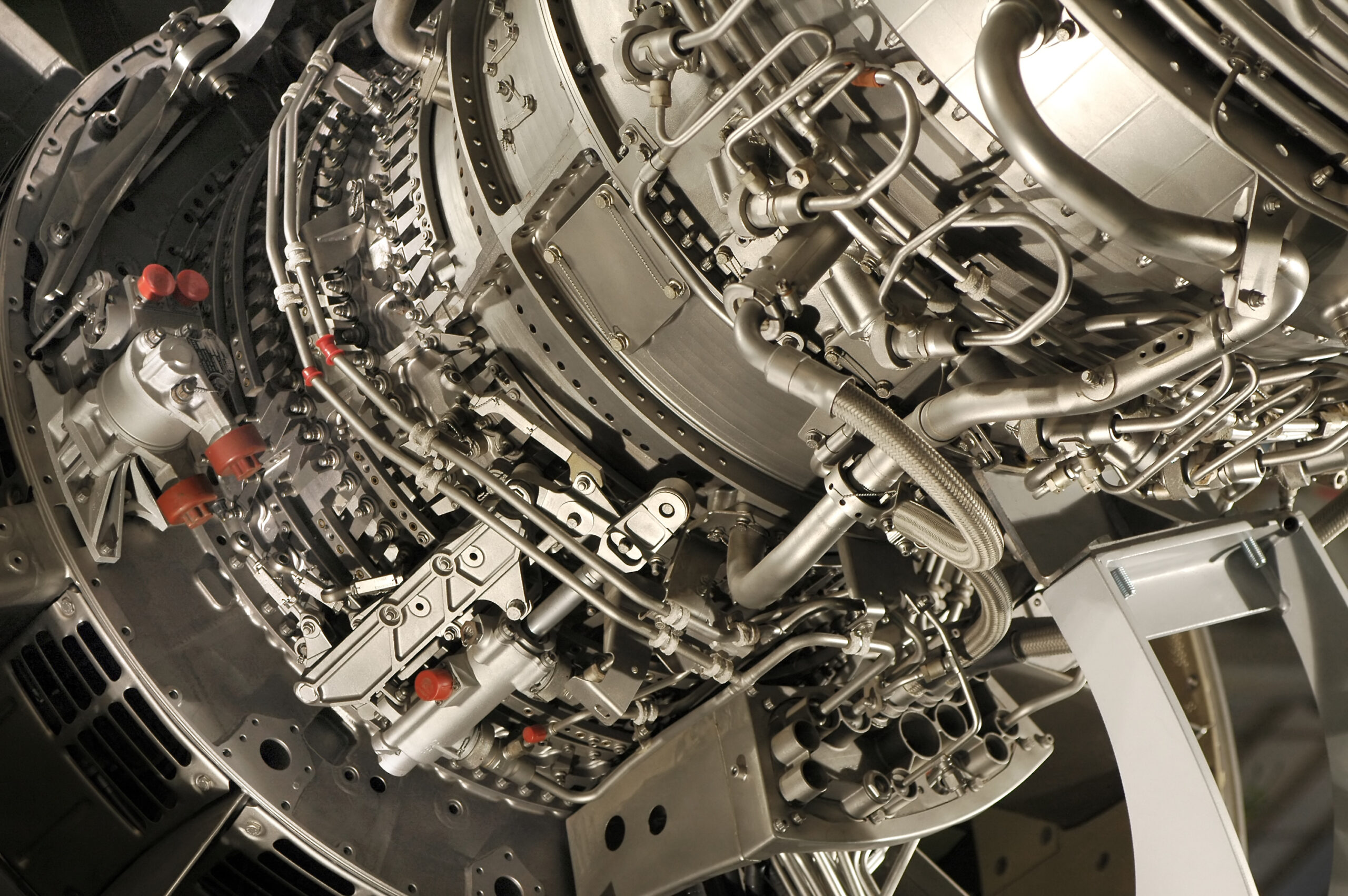

Fasteners might not be the most glamorous part of an aircraft — but they’re everywhere, and they matter. From wings to engine housings, thousands of tiny components hold each structure together. And when you’re flying at 35,000 feet, every gram of weight, every bump in the airflow and every choice of material adds up. Fuel efficiency isn’t just about engines and aerodynamics. It starts at the fastening point. Small Parts, Big Impact It’s easy to underestimate just how many fasteners go into an aircraft. Tens of thousands, each playing a role in how the aircraft moves, holds together and performs under pressure. Traditional steel options can get the job done — but they come at a cost: weight. More weight