The aerospace industry is under increasing pressure to deliver lighter, stronger and more efficient aircraft—faster than ever before. As demands for productivity and precision soar, automated aerospace fastening has emerged as a key area of transformation. Driven by advances in robotics and intelligent automation, modern fastening systems are setting new standards for speed and consistency in aerospace manufacturing.

At JP Aero, we’re at the forefront of this evolution, supplying innovative fastening systems and staying closely aligned with the technological shifts redefining the industry.

The Rise of Automation in Aerospace Fastening

For decades, traditional fastening systems relied on manual processes that, while effective, were time-consuming and susceptible to variability. Today, automation is eliminating many of those inefficiencies.

Automation solutions now integrate AI-powered robotics, vision systems and smart data feedback loops to enable real-time decision-making—and adaptive performance during the assembly process. Machines can drill, place and secure fasteners with exceptional accuracy—consistently achieving hundreds of fasteners per minute with minimal deviation.

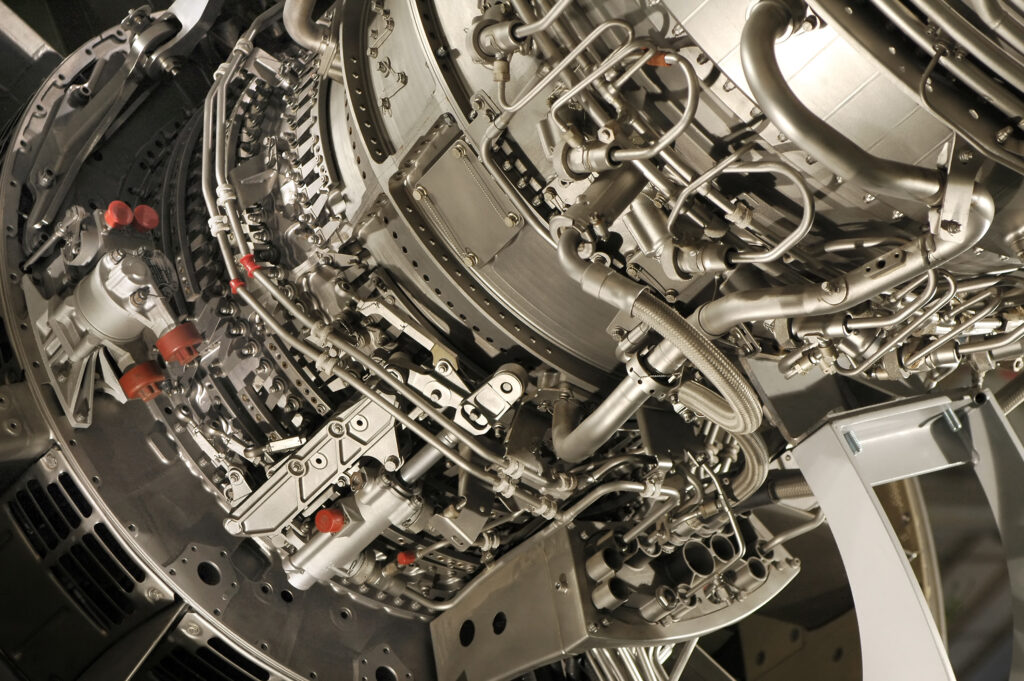

One standout example is the use of robotic arms with end-effectors designed specifically for temporary fasteners in fuselage assembly. These robots not only position and secure the fasteners but also adjust in real time based on surface tolerances or material changes, improving the functionality and reliability of joints.

Functionality and Speed: The New Benchmark for Fastening Systems

Speed and functionality are no longer optional—they’re essential. Modern aircraft production requires scalable solutions that maintain quality across increasingly complex geometries. Airbus, for example, has implemented advanced automated drilling robots capable of performing 7,500 precise holes in the A350’s rear fuselage section, significantly enhancing production efficiency and precision.

Automated fastening systems provide several advantages:

- Increased throughput: Automated machines can install fasteners much faster than manual methods, dramatically reducing cycle times.

- Improved precision: AI algorithms help robots make fine-tuned decisions during placement, enhancing joint integrity.

- Lower cost of error: Automation reduces the need for rework, saving both time and materials.

A wide range of modern fastening products now support this new standard, from high-performance speed fastening solutions to highly specialised equipment tailored for complex aerospace assembly applications.

Intelligent Machines: Transforming Aerospace Operations

What truly sets modern automated aerospace fastening apart is the intelligence now embedded into the machines themselves. Robotics can learn from historical production data, adapt to anomalies and even detect when tooling wear might compromise joint quality.

For instance, adaptive drill and insert units now use torque sensors and machine vision to dynamically control insertion force and angle. This minimises material stress while maximising long-term durability—crucial in aerospace structures where failure is not an option.

Automation also extends to quality assurance. Sensors embedded in the assembly equipment provide live feedback to operators so that every fastener is installed to spec, which also enables traceability throughout the build.

The Future of Aerospace Fastening: Robotics and Beyond

The integration of automation solutions with data-driven decision-making marks a new era in aerospace manufacturing. As products become more complex, and pressure for faster delivery mounts, automated aerospace fastening will play an even greater role in ensuring that quality, compliance and efficiency go hand-in-hand.

As such, manufacturers are increasingly adopting advanced fastening systems that meet evolving requirements—whether that’s compatibility with robotic assembly lines, enhanced functionality or increased speed.

JP Aero: Supporting the Next Generation of Aerospace Fastening

With decades of experience in supplying the aerospace industry, JP Aero understands the critical role fasteners play in modern aircraft construction. From temporary fasteners used in wing and fuselage assembly to precision speed fastening tools, we help clients stay ahead with reliable, innovative and future-ready products.

Whether you’re scaling up production, integrating automation or upgrading your fastening systems, JP Aero is your trusted partner in achieving aerospace excellence—faster, smarter and more reliably than ever.

Explore our aerospace fastening range and speak to a specialist about how we can support your automated operations.