In the world of aerospace engineering, material selection is never just about weight or cost — it’s about survival in extreme environments. When operating temperatures climb past the limits of conventional alloys, two fastener materials rise to the challenge: titanium and Inconel.

But which is better suited for withstanding extreme temperatures — titanium fasteners or Inconel fasteners? Let’s break down their performance, composition, and advantages in critical aerospace applications.

Looking for high-performance fasteners built for extreme conditions? Explore our aerospace-grade Inconel and titanium options today.

Understanding the Contenders: Titanium Fasteners and Inconel Fasteners

Titanium fasteners are well known for their exceptional strength-to-weight ratio and natural corrosion resistance. They’re widely used in aircraft structures, jet engines, and high-performance automotive systems — particularly where weight savings are essential.

Inconel fasteners, on the other hand, are part of a family of nickel-based superalloys specifically engineered for high-temperature environments. These include Inconel 600, Inconel 625, and the widely used Inconel 718, all of which offer outstanding mechanical properties at elevated temperatures.

High Temperature Stability: Which Alloy Holds Up?

When it comes to high temperature stability, Inconel fasteners have a clear edge. Thanks to their high nickel content and unique alloying elements, Inconel retains strength, oxidation resistance, and structural integrity in temperatures exceeding 700°C (1300°F).

- Inconel 718 is the aerospace workhorse, maintaining strength up to 650°C.

- Inconel 600 and Inconel 625 offer exceptional oxidation resistance and can perform at even higher temperatures, making them ideal for turbine blades, exhaust systems, and thermal shielding.

Titanium fasteners begin to lose mechanical strength at around 400–500°C. While still suitable for many aerospace applications, they simply can’t match Inconel’s fatigue strength or structural reliability in ultra-high-heat conditions.

Corrosion Resistance: A Close Contest

Both titanium and Inconel offer excellent corrosion resistance, but in different ways.

- Titanium fasteners form a stable oxide layer that protects against saltwater, acid rain, and galvanic corrosion — especially in marine or coastal aerospace settings.

- Inconel alloys, including Inconel 600 and 625, offer better performance in extreme industrial environments where chemical corrosion and oxidation are common. Inconel’s nickel content plays a key role here, providing superior protection against aggressive agents such as acids, alkalis, and chlorides.

In short, titanium performs better in environments where weight and general corrosion protection are paramount. Inconel thrives under chemical attack and thermal stress.

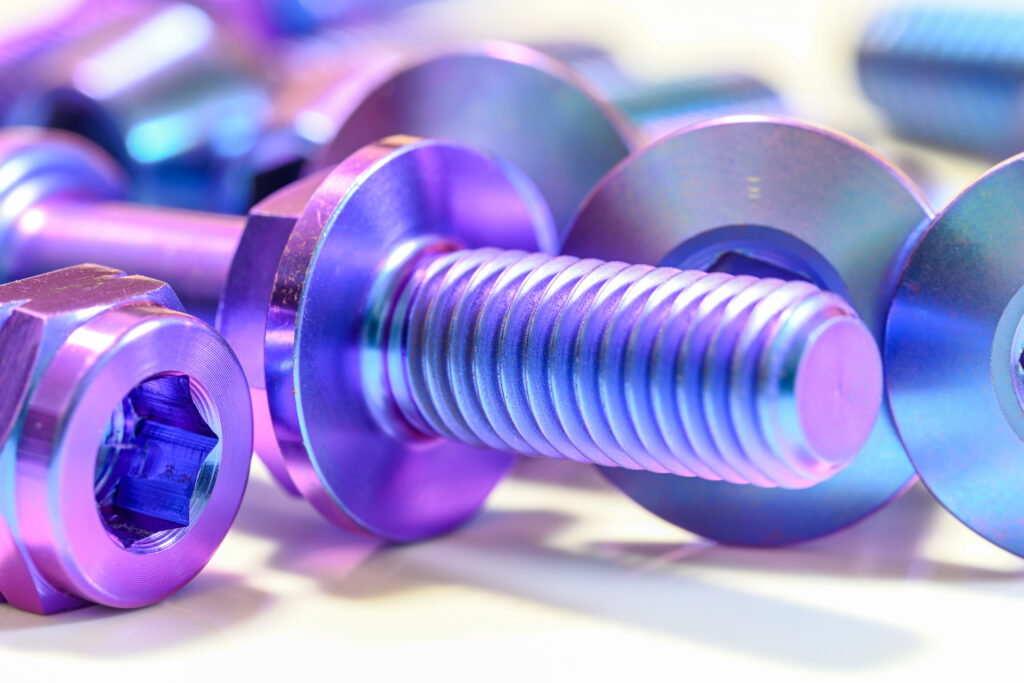

Fasteners in Focus: Hex Bolts, Nuts, and Screws

In aerospace assemblies, fastener types like hex bolts, nuts, and screws must be carefully selected not only for their form but for their material’s behaviour under stress.

- Titanium hex bolts offer lightweight performance and are commonly used in airframe construction.

- Inconel screws and Inconel bolts are chosen for turbine engines, rocket propulsion systems, and high-heat sealing applications where failure is not an option.

Choosing the right fastener isn’t just about strength — it’s about performance at extreme temperatures, chemical exposure, and fatigue over time.

Mechanical Properties: Comparing the Specs

| Property | Titanium Fasteners | Inconel Fasteners |

| Density | ~4.5 g/cm³ | ~8.2 g/cm³ |

| Yield Strength | 800–1,200 MPa | 1,030–1,270 MPa (Inconel 718) |

| Operating Temp Range | Up to ~500°C | Up to ~700–980°C (material dependent) |

| Corrosion Resistance | Excellent (marine & humid) | Excellent (chemical & thermal) |

| Fatigue Strength | Moderate | Very High |

| Weight Consideration | Lightweight | Heavy |

Inconel 718: The Benchmark for Extreme Environments

If there’s one material that defines extreme aerospace fastening, it’s Inconel 718. Known for its exceptional mechanical properties, creep resistance, and weldability, it is the gold standard in jet engines, spacecraft, and nuclear applications.

At JP Aero, we regularly supply aerospace-grade Inconel fasteners — including hex bolts, nuts, and screws — all manufactured to the most stringent specifications.

Which Fastener Should You Choose?

If your application demands lightweight performance, excellent corrosion protection, and service temperatures below 500°C, titanium fasteners are ideal.

However, if your project involves thermal extremes, oxidising atmospheres, or mechanical stress at high temperatures, Inconel fasteners — especially Inconel 600, 625, or 718 — are the clear winner.

Aerospace Fasteners You Can Trust

At JP Aero, we supply high-performance fasteners to meet the most demanding aerospace and defence requirements. Whether you need titanium fasteners for airframe builds or Inconel bolts and screws for turbine engines, our precision-engineered components deliver performance where it matters most.

Source the right fastener for extreme temperatures

Contact our team today to discuss your project and get expert support.

Explore our aerospace fastening range and speak to a specialist about sourcing the right fasteners for your operations.