Welcome to our guide to UK Space Ancillary Services in 2022.

A leading UK main distributor of standard and bespoke

fasteners for international aerospace and other industries.

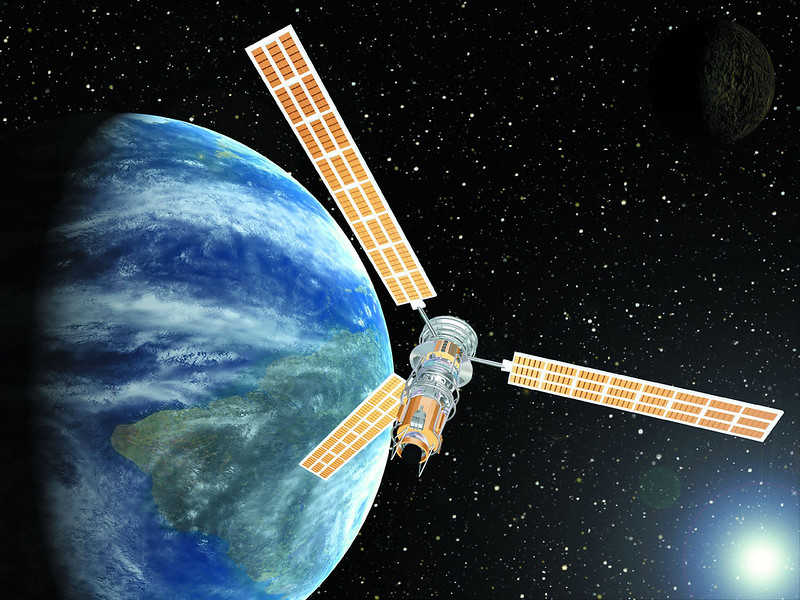

If you are looking for a comprehensive guide to the Space Applications market in the UK, then you are in the right place.

What’s happening in UK space operations this year? We take a look at some of the big developments coming our way.

Small satellite fasteners are in huge demand as we witness exponential growth in this exciting and revolutionary new field. But how do you meet the surge in demand without compromising on quality?

The aviation supply chain is facing a difficult winter as demand across the world picks up to pre-pandemic levels just at the time when shipping and manufacturing bottlenecks are at their worst.

Find out how these tiny nuts, bolts and screws are some of the toughest, lightest and best performing pieces of micro-engineering on the planet.

A roundup of some of the best things happening with space start-ups in the UK right now. Find your UK space start-up info here.

The UK space sector may not be making the news headlines as often as Elon Musk, but this thriving and ambitious industry is punching well above its weight.

So, without further ado, let’s take a look at some of the most innovative and exciting things going on in the UK space industry today.